This RP does not cover ancillary equipment for flexible pipes and umbilicals beyond the connector with the exception of riser bases and load-transfer devices. 5 depicts a tensile armour wire rupture of a flexible pipe caused by abrasion.

Retrofit J Tube For Offshore Installation Gce Ocean Technology

Therefore this document does not cover turret structures or I-tubes and J-tubes for example.

. It may even become the critical path depending on market conditions for tubes cables bundling etc. Umbilicals should undertake self-weight and periodic loading during operation because of the severe conditions. Study it was found that flexible pipe could be pulled up a spare conduit that had bends totalling to more titan 360 degrees along its length.

The merit of the method is to improve the tension stiffness and the fatigue. J-tube design for flexible umbilicals Written By weisinger Friday April 8 2022 Add Comment Edit The basis for assessment of fatigue damage of such elements is the long-term stress cycle distribution at critical locations on the helix elements caused by long-term environmental loading on the system. Posed a design method for the layout design of a complex cross section of umbilicals by quantifying symmetry and compactness which are not mentioned in the specifications 1.

An overall computational consistent and efficient fatigue analysis scheme is outlined with due regard of the cross-sectional analysis technique required for fatigue stress calculation with particular attention to the helix elements. The radius of the J is a function of whether the risers to be pulled up the J tube are flexible or more normally rigid pipe- on the platform Im on. This specification does not cover flexible pipe and umbilical ancillary equipment beyond the connector with the exception of riser bases and load-transfer devices.

Umbilicals which link top floaters and subsea devices provide control functions through electrical cables and hydraulic remote transmission. J-tubes experience both pull-in and pull-out loads in practice and the latter. We offer seals to suit all tube sizes and umbilical diameters.

The design of a dynamic umbilical is an iterative process and is time consuming. These cables are considered the lifeline of subsea production systems for offshore oil and gas exploitation. The design of J-tubes with one or more bends under functional loads is dictated by a single force T L the cable tension at the bottom of the J-tube.

A novel methodology by using UFLEX2D a MARINTEK product has been applied for modeling complex umbilical. In addition this document does not cover storage devices such as reels for example. This paper focuses on evaluating the impact of friction and contact pressure on helical steel tubes.

STU technology allows to design compact and optimized cable cross-section by using pre-shaped fillers. A design method is presented which aims at the optimal cross-sectional layout of the multilayer steel tube umbilical. In dynamic applications the individual steel tubes can be oversheathed to prevent.

SAF 3207 HD offers greater yield strength greater corrosion resistance and superior fatigue properties compared to super-duplex. In addition it does not cover flexible pipe or umbilical storage devices for example reels. Our steel tube umbilical designs provide a reliable and durable way of connecting onshore or offshore hosts with subsea facilities.

J- tube seal is used to seal the interface between the umbilicalcable and the inside of a J-Tube incorporating a watertight seal in which an anti-corrosion inhibitor is. It is designed for the most extreme conditions in terms of depth temperature and pressure. Therefore this document does not cover turret structures or I-tubes and J-tubes for example.

The following graphic illustrates the iterative nature of umbilical design. The test regime is chosen to demonstrate that a particular design or design feature is suitable to withstand the repeated flexures sustained by an umbilical during manufacture transfer spooling load-out I- or J-tube pull-in burial and for a dynamic. Oceaneering tube seals are suitable for use with I and J tubes and are fitted to umbilicals to protect customers assets.

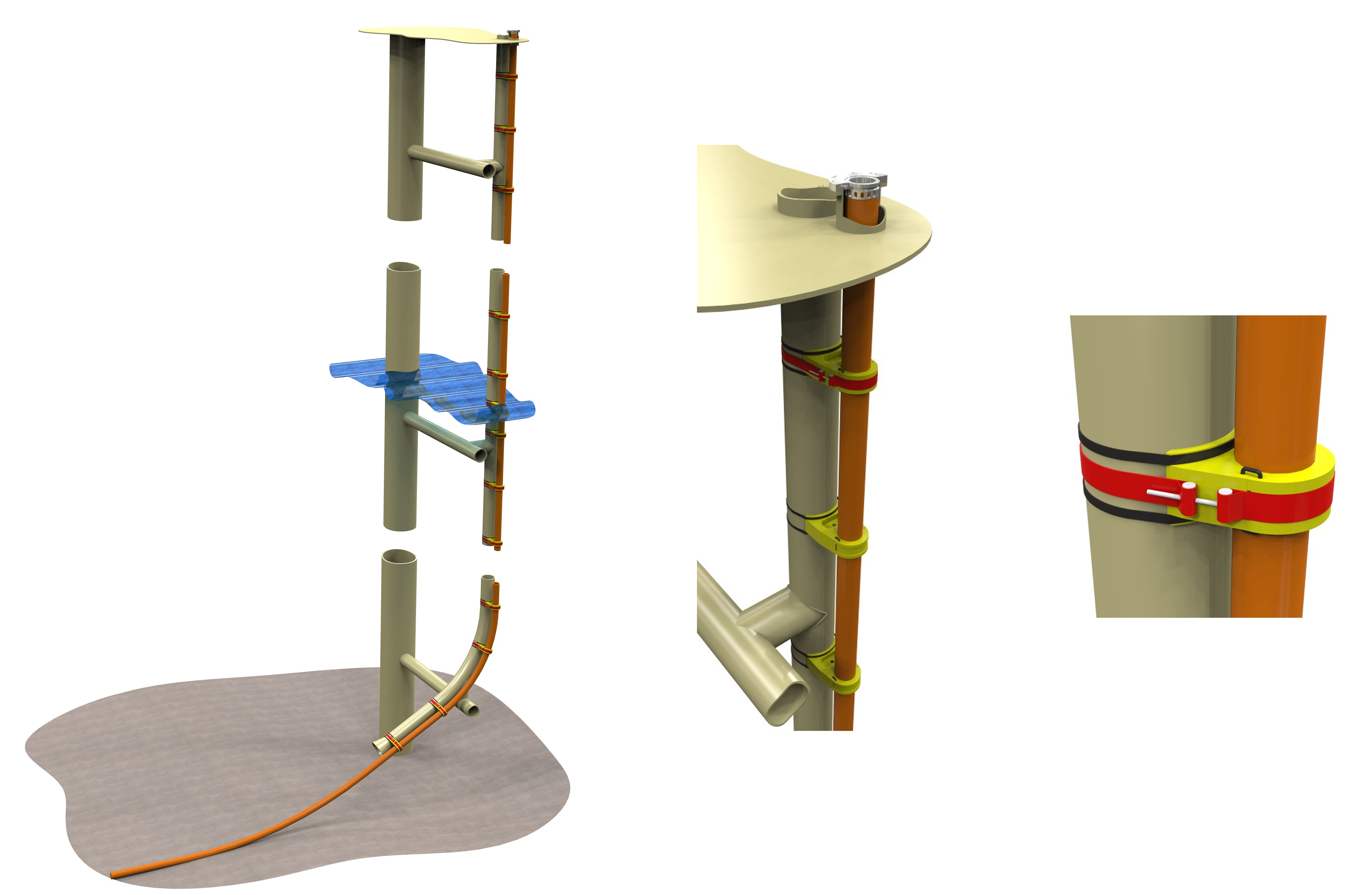

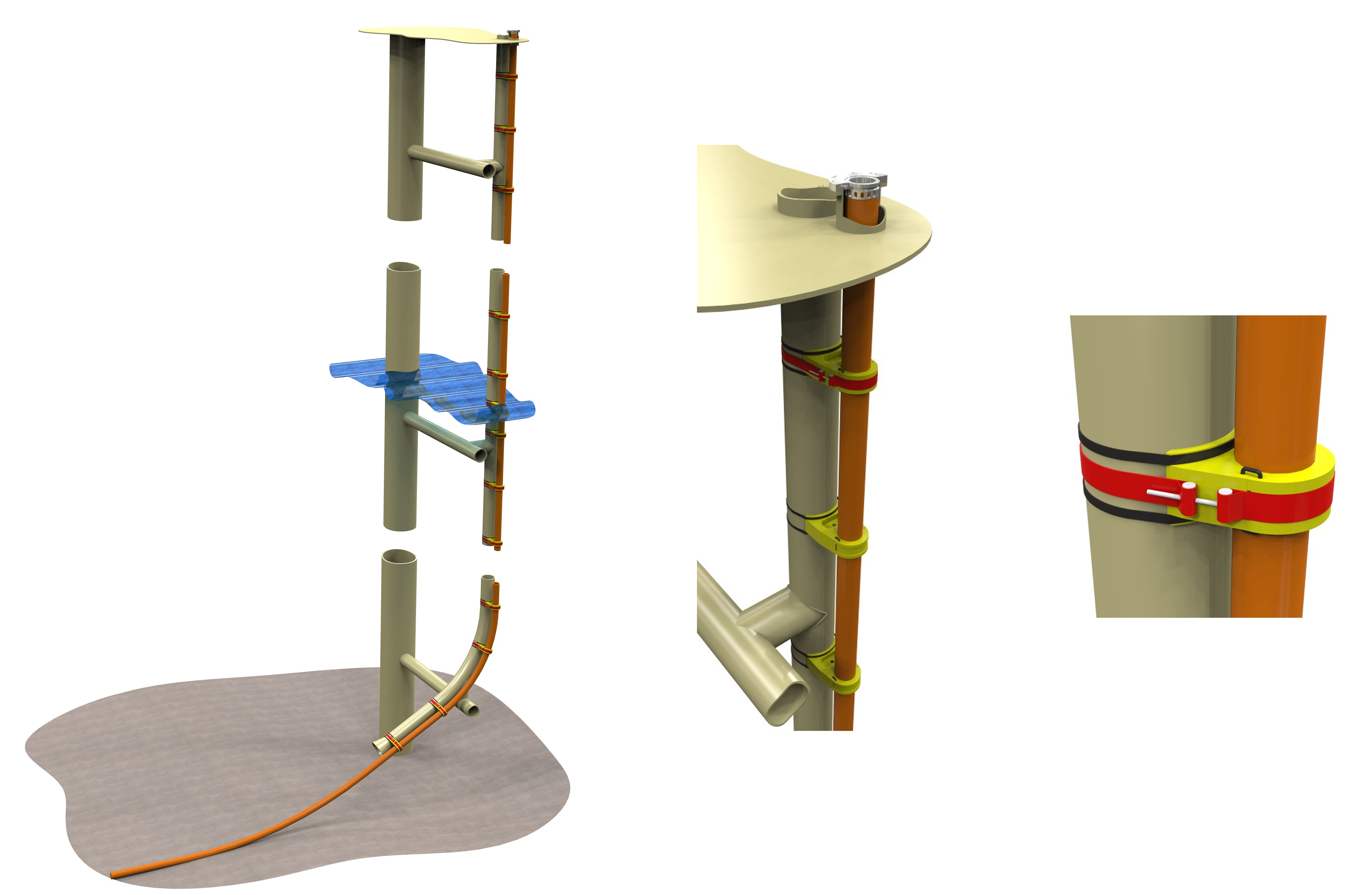

Ennsub Subsea J-Tube Installation. This has increased the opportunity for flexible pipe pull-in beyond the traditional J-tube. Flexlife was approached to design fabricate and supply a riser system which included a flexible pipe J-tube and associated clamps for an existing field tieback in the East Irish Sea.

A hyper-duplex stainless steel developed for deepwater umbilicals. A J tube is exactly that. A tube shaped like a J extending from the top of a jacket to the mudline or close to the mudline with a bell mouth on the end to provide a conduit to pull risers up.

Manufacturing of Steel Tube Umbilicals. They typically provide hydraulic fluid for control various chemical fluids for injection into the flowline electrical power and electrical- or fiberoptical signal transmission. This has allowed flexible pipe to be pulled up a J-tube originally intended for umbilicals.

In addition it does not cover flexible pipe or umbilical storage devices for example reels. Within Steel Tube Umbilicals steel tubes can also have a structural function supporting the weight of the umbilical and removing the need for tensile armoring. Our Retrofit J-tubes can be adapted to a wide range of foundation types allowing for a multitude of installation procedures and bringing extra protection to any subsea cables umbilicals or flexible pipesWith more than 25 years experience Seaproof Solutions specializes in protection systems for subsea cable umbilical and flexible pipe.

This facilitates the analysis of J-tubes using standard beam theory or for complex shapes a simple computer model. The seals enable clients to dose anti-corrosion andor biocide chemicals into the. The design had to take into account shallow water dynamic field infrastructure ageing assets a lack of survey data and restricted topside access.

The initial gaps between steel tubes and adjacent layers friction coefficients and the contact stiffness are the main factors that affect such investigation. 425 valid for tube and pipe. Fatigue analysis of structural components such as helix tensile armors and steel tubes is a critical design issue for dynamic.

Therefore this document does not cover turret structures or I-tubes and J-tubes for example. Design of subsea cablesumbilicals for in-service abrasion - Part 1. This RP does not cover ancillary equipment for flexible pipes and umbilicals beyond the connector with the exception of riser bases and load-transfer devices.

Subsea Distribution Products Oceaneering

Flexcom 8 J Tube Pull In Youtube

0 comments

Post a Comment